We use cookies to enhance your experience. Read our policy so you can understand the types of cookies we use, the information we collect using cookies and how that information is used.Privacy Policy

Close

Confirm choices

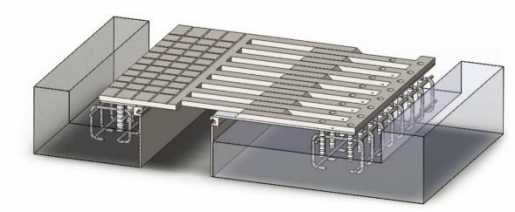

Bridge expansion joints are designed to allow for continuous traffic between structures while accommodating movement, shrinkage, and variations on reinforced and pre-stressed concrete, composite, and steel structures. They also carry the loads and provide the safety to the traffic over the gap between bridge decks and/or abutment.

Details

General information about Bridge Expansion Joint

Introduction

Bridge expansion joints are designed to allow for continuous traffic between structures while accommodating movement, shrinkage, and variations on reinforced and pre-stressed concrete, composite, and steel structures. They also carry the loads and provide the safety to the traffic over the gap between bridge decks and/or abutment.

A further requirement is a low noise level especially in an urban environment. Water tightness has to be considered so no water runs into the substructure. Replacement with minimum interruption of traffic shall be designed and realized in a simple way.

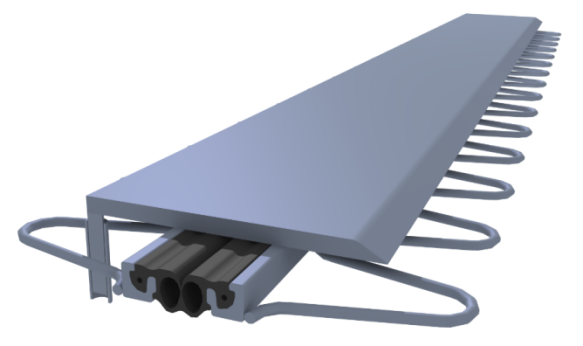

There are various types of expansion joints which can accommodate movement from 10 to 2,000 millimeters. Currently, there are 6 major groups of bridge expansion joint falling in the supply scope of IEC.

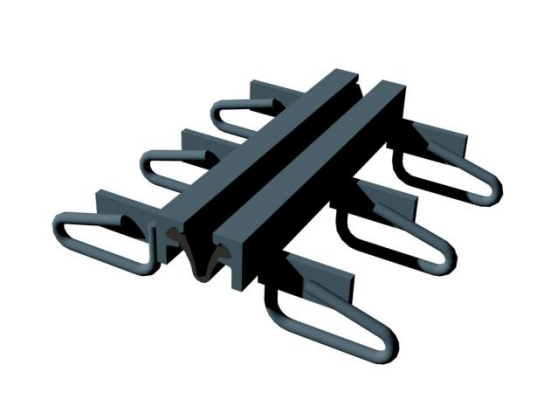

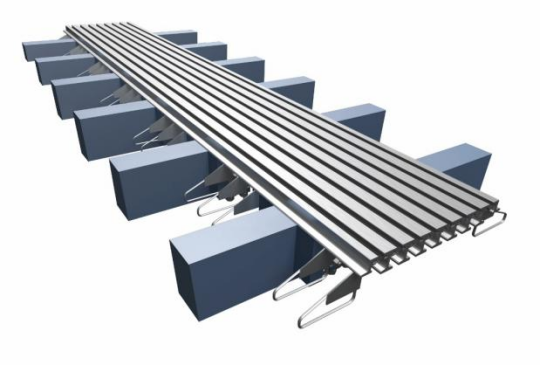

1) Stripseal joint (single-gap joint or nosing joint);

2) Modular expansion joint (MBJS abbreviated in AASHTO);

3) Finger expansion joint;

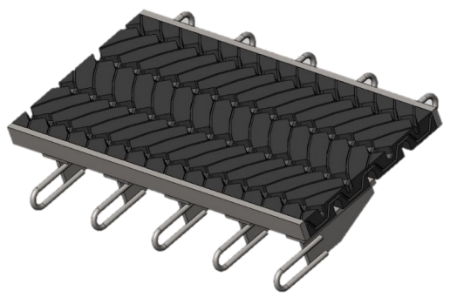

4) Mat expansion join (reinforced rubber joint);

5) Flexible Plug expansion Joint;

6) Expansion joint for railway

Stripseal expansion joint Modular expansion joint Finger expansion joint

Mat expansion joint (Reinforced rubber) Flexible (asphaltic) Plug expansion Joint Railway expansion joint

Calculation of movements of expansion joint

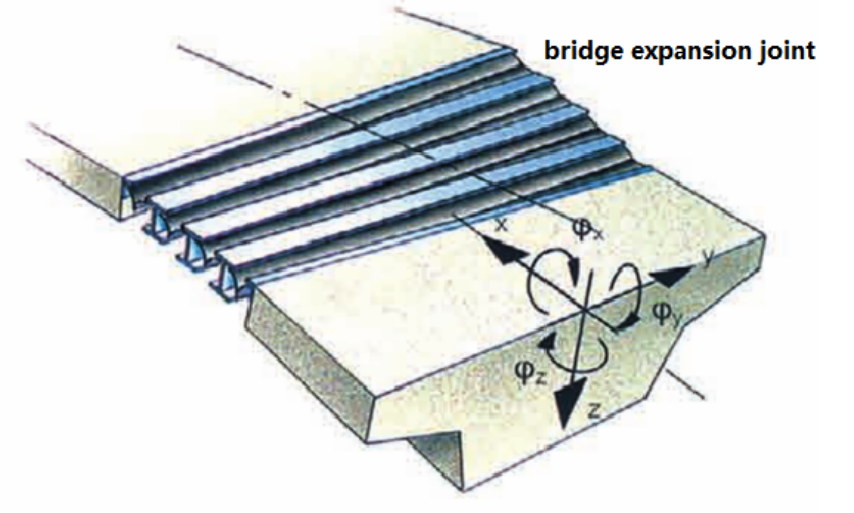

Movement of expansion joints depends on the size of the bridge and the arrangement of the bearings. Normally the form of construction depends on the horizontal translation orthogonal to the joint. But it is necessary to consider all translations and rotations to ensure that the displacements will not reach the limits of the joint construction. To describe the movements of an expansion joint in detail, three translations and three rotations have to be considered.

An illustration showing the location and function of bridge expansion joint

(permissible movement in 6 degrees)

These movements result from temperature, displacements due to external loads, creep and shrinkage in concrete or composite bridges. The movement values can be obtained from the structural analysis of the system. It is normally the consultant’s or designer’s responsibility to work out the anticipated movement values.

Corrosion prevention

Corrosion prevention is very important to keep the expansion joint operational in its designed service life, also is essential to protect the entire bridge structure.

For stripseal, modular or finger joints, following procedures for corrosion prevention are adopted as standards at IEC:

For exposed steel surfaces (such as centerbeams, edgebeams, support bars, for stripseal joint, modular joints and finger plates)

1) Blast Cleaning to Swedish Standard SA2.5 for derusting;

2) Hand Cleaning: remove all dirt, loose rust and mill scale, or oil stains if any;

3) Application of coating:

Ø apply a primer coating of zinc-rich epoxy paint at a min. 60 µm thickness;

Ø apply acrylic aliphatic polyurethane paint at a min. 80µm thickness for 2~3 times;

Ø total numbers of coatings is 3~4 and total dry film thickness is min. 240~320 microns. (the finishing coating is 60 microns)

The duration between the coatings will depend on ambient temperature and humidity. The coating color system is as per RAL 7042 if not specified otherwise.

Such treatment will meet the C5-I or C5-M level according to ISO 12944 requirement due to different corrosivity category requirement and cost concern.

Hot-dip-galvanized method can also be offered upon request as per ISO 1461:2009, “Hot dip galvanized coatings on fabricated iron and steel articles— Specifications and test methods”. Or a duplex system of painting over HDG is also available upon request when aiming a far more reliable effect.

For non-exposed steel surfaces (anchor plates, anchor loop bars, support box plates, which will be embedded in the concrete mortar)

Same procedures with above but only the total numbers of coatings is 2 and total dry film thickness is min. 120 microns.

For temporary devices (lifting devices, adjustment devices)

Apply epoxy paint at a min. 50µm thickness for 1 time, color is blue or red, after shot blasting;

For all the bolts

dacromet treated.

Painting of modular expansion joint at IEC workshop Painting of finger expansion joint at IEC

for NOH2 project in Doha Qatar, 2018 for Tama Bridge over Nile, Egypt, 2019

paint film thickness 243 microns (C5-Ml) Hot-dip-galvanized treatment

for E-ring road project in Doha Qatar, 2018 for NOH2 project in Doha Qatar, 2018

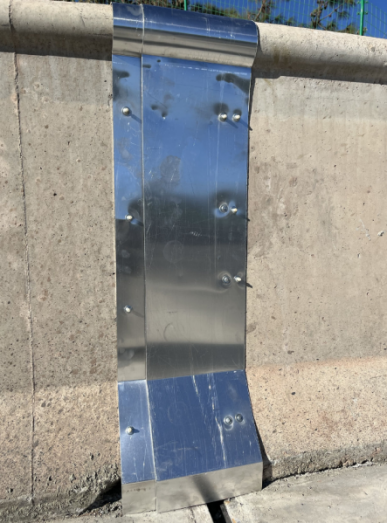

Sidewalk and parapet treatment

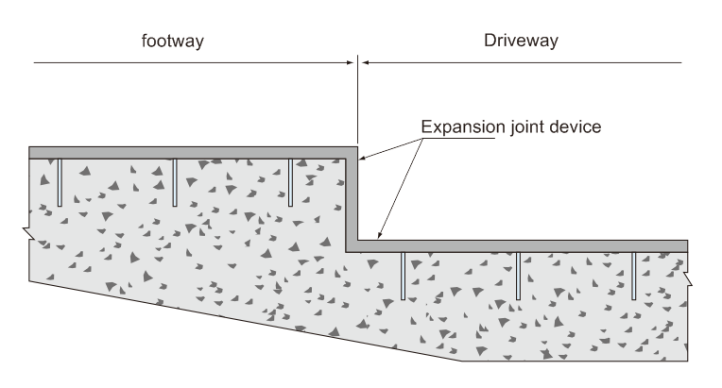

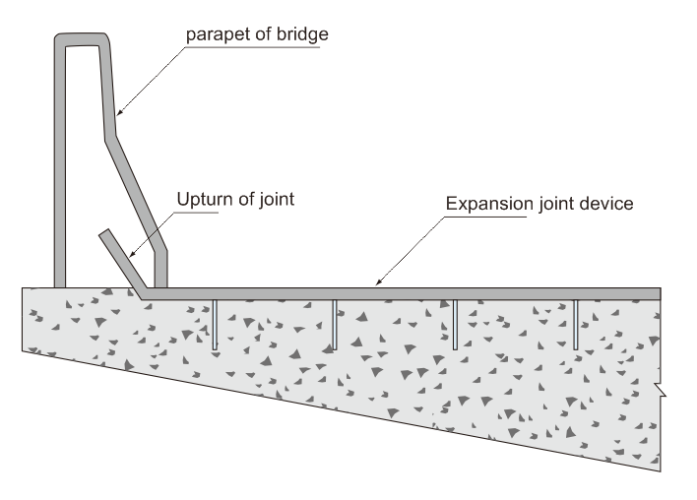

Mostly, the joints have to be designed to come along with the sidewalk (footway) or the parapet.

Upturn design of modular joint so they can extend upward into parapet or sidewalk

how the upturn extends into the reserved void in the parapet

Cover plate over the modular expansion joint in the parapet area

As for footway, a cover plate made of thin galvanized steel plate shall be provided to be bolt-connected to one side of the joint and the other side can move to accommodate the movement. The purpose of this cover plate is to facilitate a fully-covered passage for pedestrians or bicycles.

For detail designs, consult IEC specialist engineer.

Handling, packaging and storage

Bridge Expansion joints are protected prior to be delivered and proper measures to prevent damages during transit have been taken.

Lifting-up the joint shall consider the safety to the handler as well as to joint itself. For finger joints, since they are supplied in units, using forklift can discharge the package and use hand to place joints in their positions. For strip and modular joints, always use crane for lifting. For details, contact IEC for Method Statement for different types of joints respectively.

Joints shall be stored in safe, dry and clean environment to keep away from moisture and foreign contaminants.

Packed for Irbid Ring, Amman, Jordan, 2016 packed for Rayyan Road, Qatar, 2020

Packed in closed wooden/steel case or frame for container loading

Other methods are also available depending on size/weight/length of joints

Applied codes/standards

IEC strip seal expansion joint can be designed to fulfil all load requirements in accordance with Chinese specifications(JT), AASHTO LRFD Bridge Design/construction specifications, European standards(ETAG 032), IRC:SP:69-2011 Indian standard and BD 33/94 specifications.

The unique project requirement can also be considered into design by IEC’s specialist engineers who have such expertise.