We use cookies to enhance your experience. Read our policy so you can understand the types of cookies we use, the information we collect using cookies and how that information is used.Privacy Policy

Close

Confirm choices

Elastomeric Isolator is also named as Seismic Isolation Bearing, or Base Isolator. Base isolation, also known as seismic base isolation or base isolation system, is one of the most popular means of protecting a structure against earthquake actions. It is a collection of structural elements which should substantially decouple a superstructure from its substructure resting on a shaking ground thus protecting the integrity of a building structure of a bridge structure.

Details

Elastomeric Isolator

General Concept

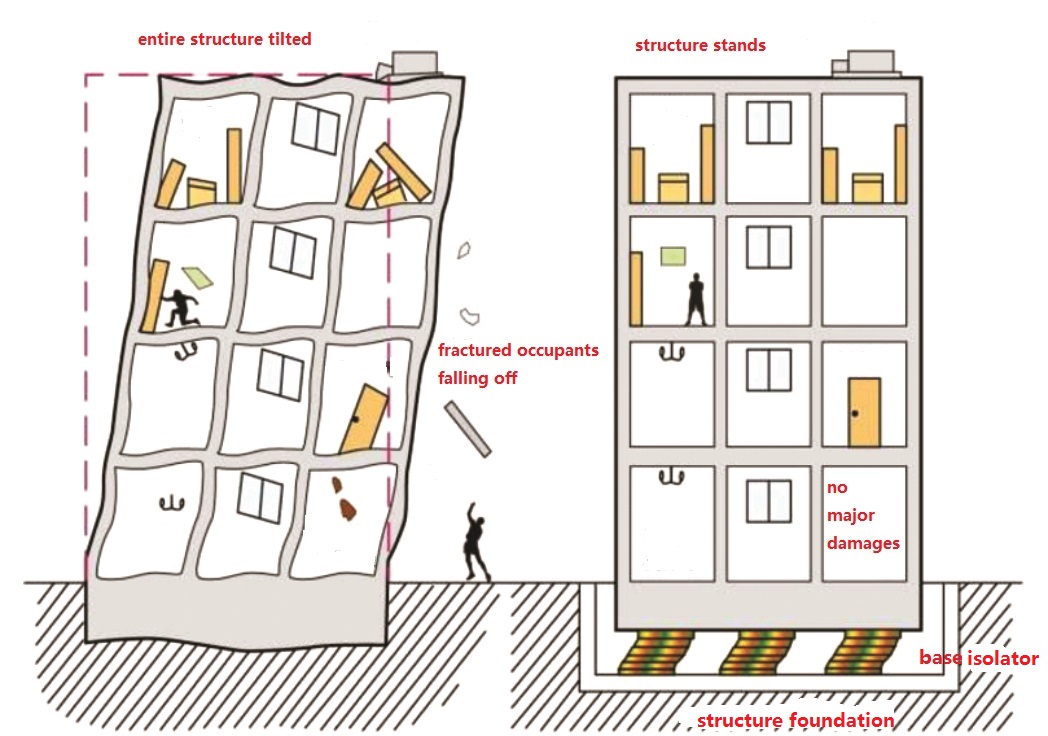

Elastomeric Isolator is also named as Seismic Isolation Bearing, or Base Isolator. Base isolation, also known as seismic base isolation or base isolation system, is one of the most popular means of protecting a structure against earthquake actions. It is a collection of structural elements which should substantially decouple a superstructure from its substructure resting on a shaking ground thus protecting the integrity of a building structure of a bridge structure.

Base isolation is one of the most powerful tools of earthquake engineering pertaining to the passive structural vibration control technologies. It is meant to enable the structure to survive a potentially devastating seismic impact through a proper initial design or subsequent modifications. In some cases, application of base isolation can raise both a structure's seismic performance and its seismic sustainability considerably. Contrary to popular approach such as increasing the strengthening resistance (larger foundation or thicker pillars. etc.), base isolation does not make a building earthquake proof but to protect the structure and its occupants inside from damage during seismic events.

Such base isolation technologies were utilized in the actual applications since 1960’S and proven during many happened earthquakes to be an effective method against seismic actions. Lead-core Rubber Bearing (LRB) and High Damping Rubber Bearing (HDRB) are among the most recognized means.

Illustration of how the isolators work during a seismic event

Design principles

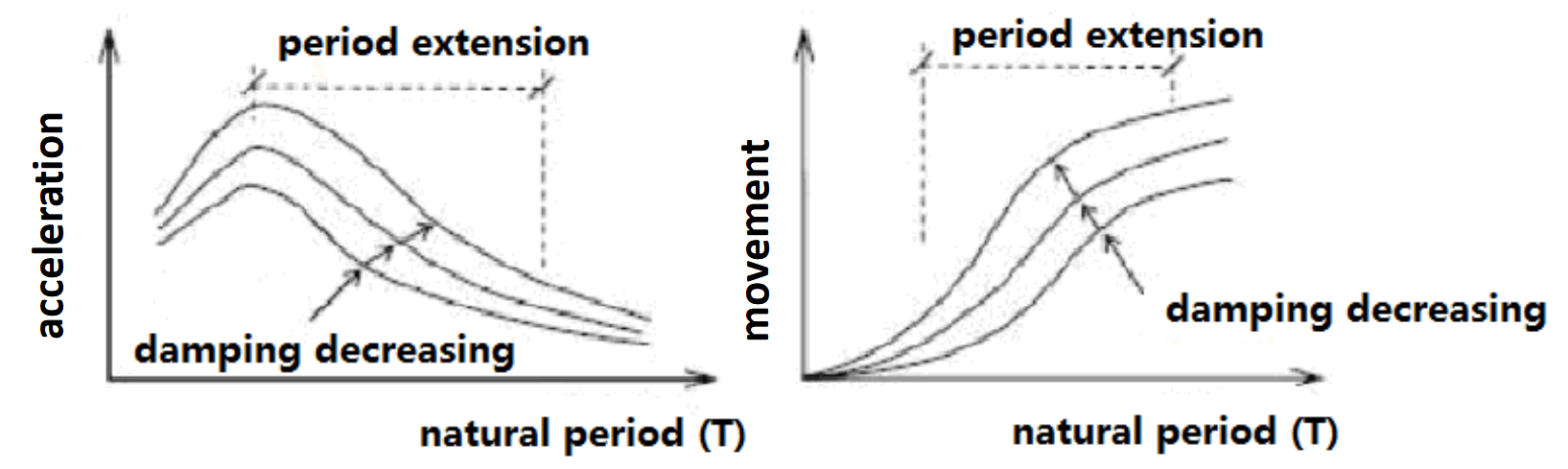

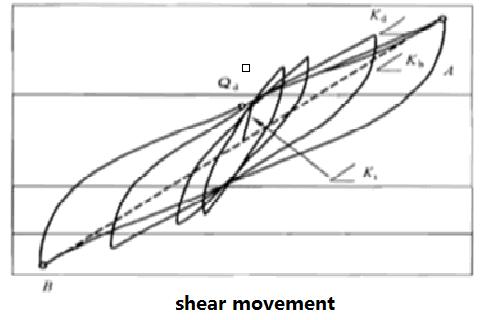

Elastomeric isolators work on the principle of base isolation which reduces the force from the foundation motion and vibration to the superstructure during the seismic events. This is realized by lengthening the period and increasing the damping of the structure. Below chart displays the relationship between structure’s natural period and the acceleration, movement and damping. When the period is designed to exceed a certain value (by installing the isolators), the seismic response decreases along with extended period. Similarly, the seismic response decreases along with increased damping on the condition the period is fixed.

Illustration displays the relationship between period, acceleration, movement and damping

The elastomeric isolators are designed either at the aim to prolong the period or boost the damping of the structure. The criteria to determine the effectiveness of an elastomeric isolator shall include the following main functions:

1) Functional as common elastomeric bearings, to resist loads combination as designed;

2) To be horizontally rigid enough (sufficient shear stiffness) to meet the target prolonged period of the isolated structure;

3) To restore to the original position after the seismic event (re-centering capabilities); In other words, the residual movements must be kept as minimal so does not affect the serviceability of the structure.

4) To effectively dissipate the energy within the designed shear movement.

Anchoring types

All IEC elastomeric isolators are equipped with suitable anchor plates/studs/bars for fixing purpose to superstructure and substructure. Anchoring methods have taken into considerations that the replacement elevation of substructure shall be less than 10mm typically. Refer to Elastomeric Bearing sector.

Benefits of choosing to use elastomeric bearings over the steel-made bearings:

ØRubber can deal with the unexpected over stress unlike the metallic materials which will undergo irrevocable plastic deformation;

ØElastomeric isolators can almost be free from maintenance in its designed service life due to the excellent behavior of natural rubber to resist the atmospheric contaminations. Oxidation in natural rubber just affects the surface. As long as the corrosion prevention of the anchor plates stand valid, the isolators can survive the design life and even more (min. 20 years typically)

ØLarge displacement can occur on isolators while the born restorative properties of rubber makes it a unrivaled material for isolating structures. By adding the lead in the dissipation of energy during earthquakes can be highly expected.

ØSave space. The combination of seismic load and movement results in a smaller sized bearing, compared with steel bearings.

ØElastomeric isolators can cater for different stiffness in different directions, or in different specific locations in one structure, while metallic bearings cannot do so.

Type test and ex-factory test (Factory Process Control):

ØTesting items as per EN15129:2009 requirement

ØIndividual and average tolerance in properties as per EN15129:2018 requirement

Test items | Initial type test before massive production | Factory production control (PFC) test before shipment |

Compression at zero displacement | required | No required |

Shear stiffness Kr | required | Required 20% |

Shear stiffness Kr and damping ratio ξ under cyclic deformation | required | Required 20% |

vertical stiffness Kv | required | Required 20% |

Variation of Shear stiffness Kr and damping ratio ξ with frequency | required | required |

Variation of Shear stiffness Kr and damping ratio ξ with temperature | required | No required |

Variation of Shear stiffness Kr and damping ratio ξ with cyclic loads | required | No required |

Horizontal deformation with vertical load at ULS with zero displacement Nsd and vertical load at SLS with zero displacement Nd | required | No required |

Variation of Shear stiffness Kr and damping ratio ξ over time | required | No required |

Standards and Specifications

ØIEC elastomeric isolators are designed and manufactured in according to ISO22762:2018, which is the equivalent to China Specification GB 20688:2006, or JT/T 822:2011;

Ø EN 15129:2018, Anti-Seismic Devices is also applicable for design and manufacture;

Ø AASHTO Guide Specifications for Seismic Isolation Design is also applicable;

Installation, maintenance and replacement

Refer to Structural Bearing sector

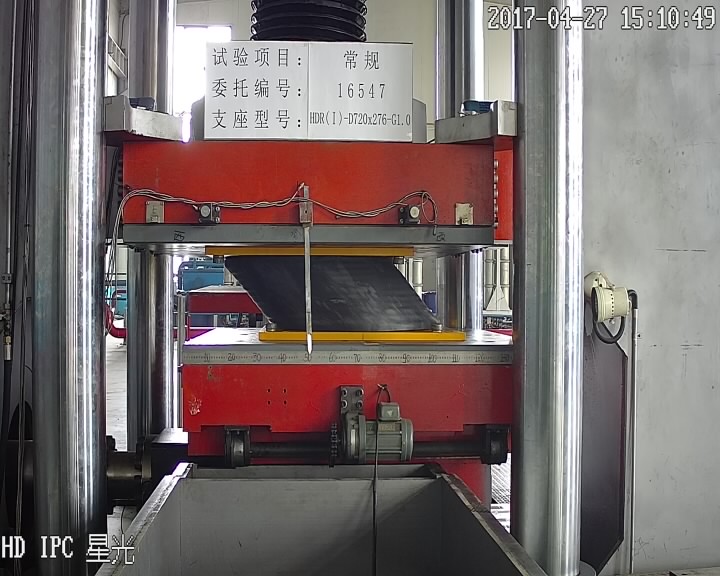

LRB (900mm diameter) tested at IEC’s in-house test laboratory

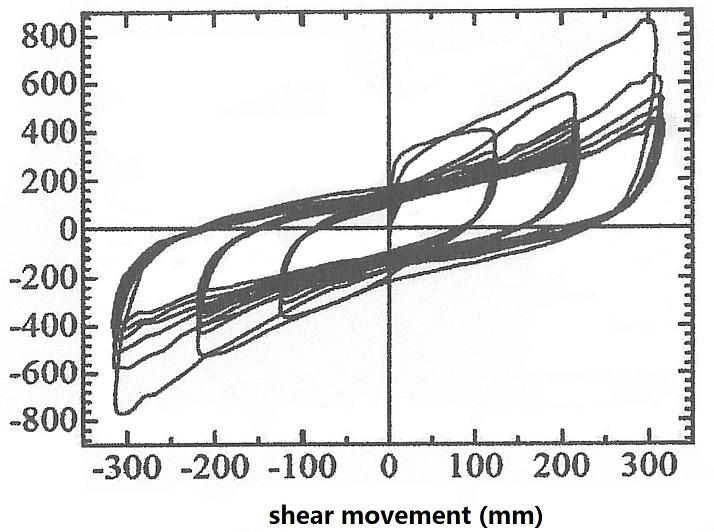

HDRB (720mm diameter) tested at IEC’s in-house test laboratory

400% shear testing shows no signs of failure of HDRB produced by IEC

Lead-core Rubber Bearings (LRB)

Structure and design principles

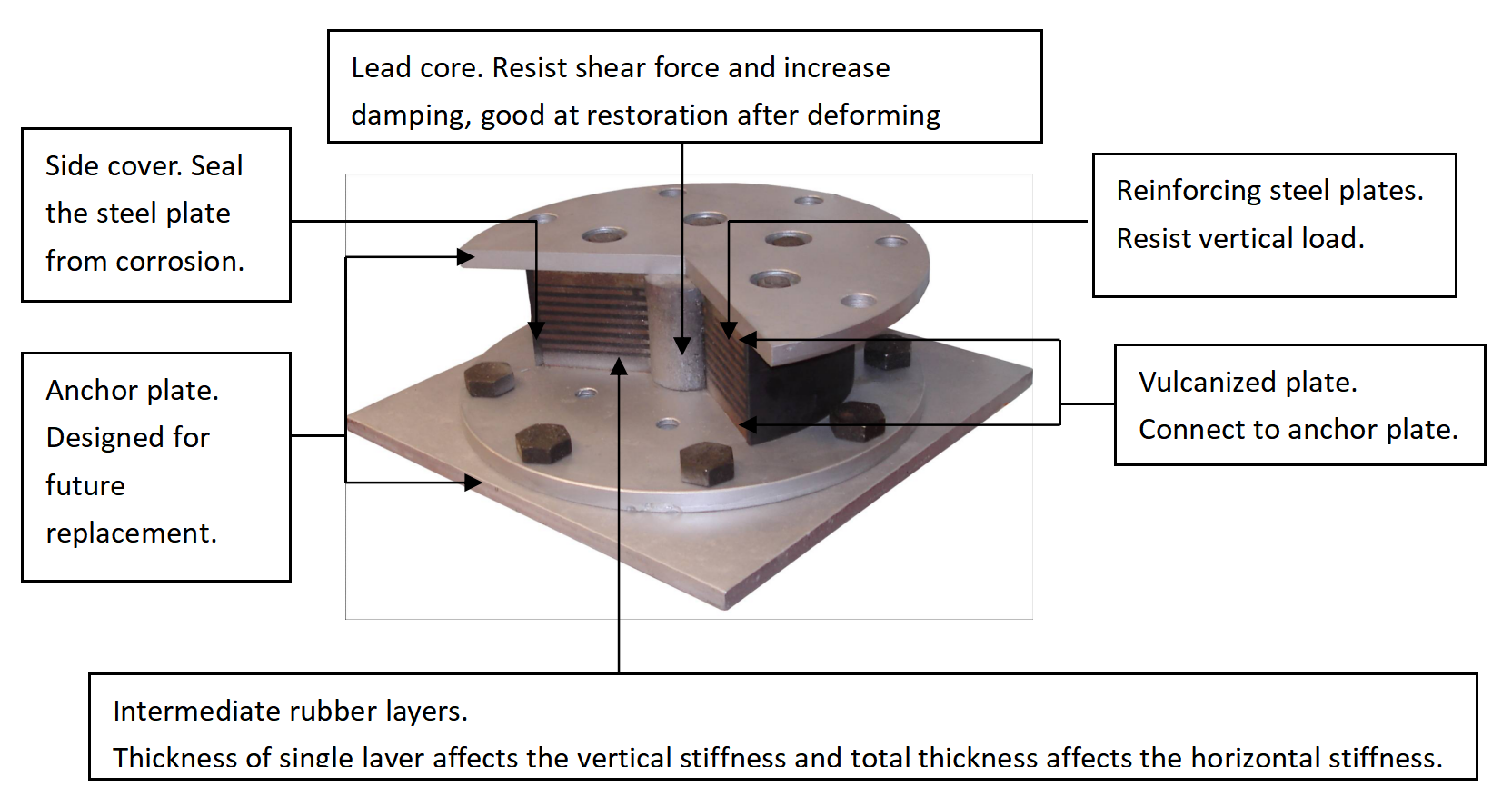

LRB, as one type of extensively used seismic isolators, is so named due to the insertion of one or more lead cylinders into the rubber bearing. The lead cylinder provides effective damping (up to 40%) during large movement in seismic events. The shape of such LRBs can be rectangular or round according to project requirements. The lead insert in the core of the bearing dissipates the energy of the earthquake while the rubber,

reinforced with steel plates, provides stability, supports the live vertical loads and low displacement horizontal loads (e.g. wind effects), isolates the structure by absorbing the impact of earthquake vibrations and by reducing oscillations.

After the earthquake, the rubber layers, due to the restorative properties, can return to its original position, so does the structure itself. This function is also called as re-centering ability.

During the design and engineering phase the type of rubber compound with the appropriate G modulus value is selected according to the installation’s technical requirements and project specifications.

The damping factor of LRBs can be up to 30%~40%. A distinctly higher resistance force is acting due to the lead core, providing a bigger hysteretic loop with such higher damping effect.

Following design features can be expected on IEC’s LRBs:

lBy modifying the rubber composition (natural rubber), anisotropic multipurpose can be reached thus LRBs can be used either in the building structure or the bridge structure.

lSeismic design load can reach up to 40,000 kN (max. size of vulcanizing machine);

lPlan diameters can reach up to 1500mm (rectangular or round);

lDamping effect can reach up to 40% by the volume of lead;

lWith replaceable anchor plates to facilitate replacement of LRB;

lA range of lead core sizes are available so to suit different damping or stiffness situations;

lHigh capacity of reducing seismic forces while providing large horizontal movement during earthquake;

Real hysteretic curve of LRB for shear deformation tested at Huazhong S&T University, Wuhan.

Material used in all IEC’s LRBs:

ØLead with 99.9% purity;

ØReinforcing plates, anchor plates, vulcanized plates, are as per S235 or A36;

ØRubber type to be Natural Rubber (NR), grade 3 per ASTM D4014-81; Can meet temperature between -25℃ to 60℃, however the hardening effect of the rubber must be

considered during the seismic design stage;

Rubber properties:

item | required value | |||

Shear Modulus G Mpa | 0.8 | 1.0 | 1.2 | |

Ultimate elongation at break, Min. (%) | 550 | 500 | ||

Tensile Strength, Min. (Mpa) | 18 | |||

peel strength between rubber and steel,kN/m | 10 | |||

Heat Resistance (aged 168 h@70℃) | Max. change in Shore hardness IRHD | -5 ~ +10 | ||

Max. change in tensile strength (%) | -15 | |||

Max. change in ultimate elongation (%) | -20 | |||

Constant compression set (aged 24 h@70℃) (%), max | 30 | |||

Ozone resistance (100pphm, 20% strain at 40±2℃ 96 h) | no crack | |||

Brittleness | -40℃ | |||

Corrosion resistance for anchor plates

Refer to structural bearings sector.

Dimensions

Consult IEC for details.

IEC supplied sets of 144 LRBs for Jiqing Bridge over the Yellow River, China

High Damping Rubber Bearing (HDRB)

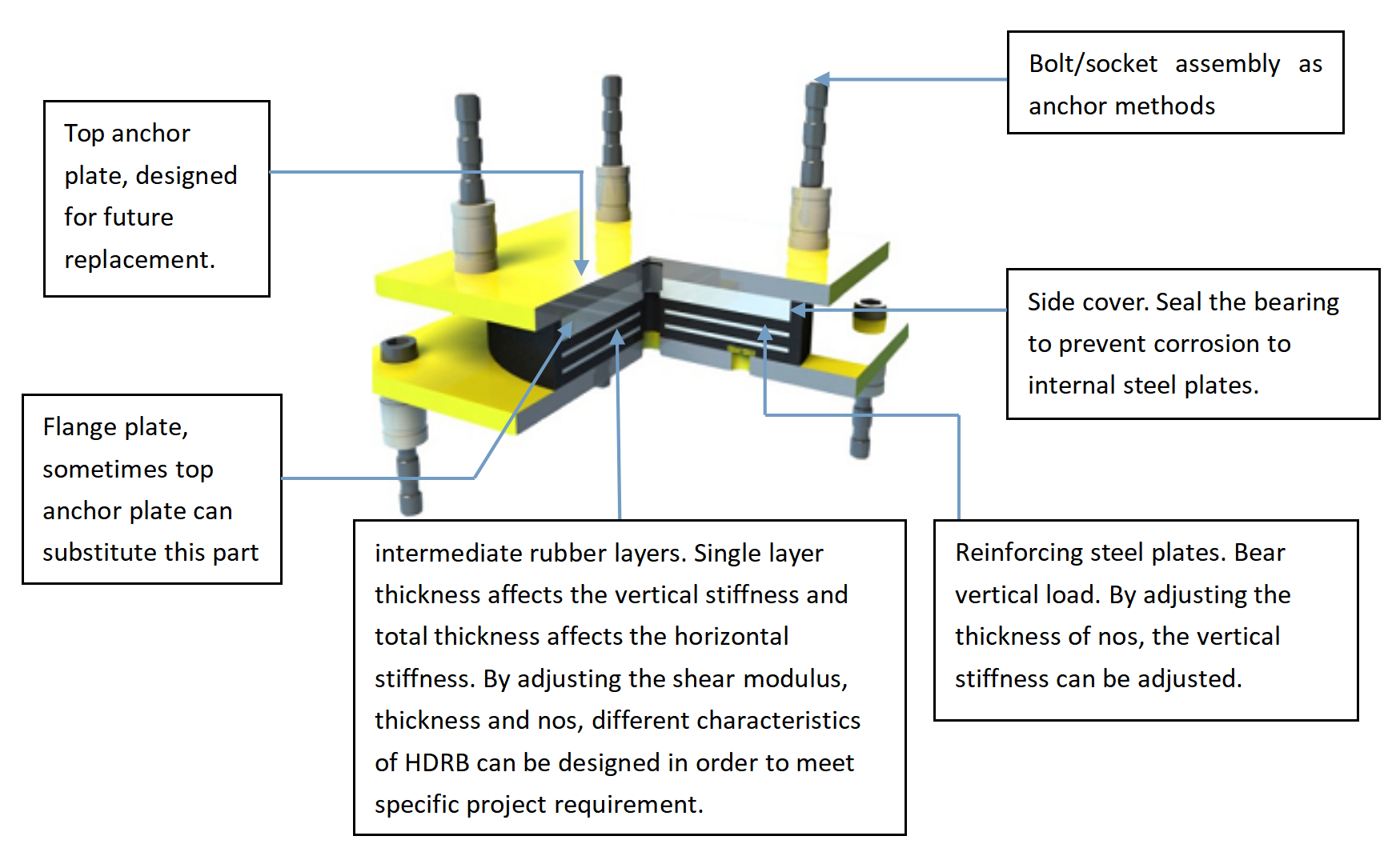

Structure and design principles

HDRB is another type of elastomeric isolators. It can be simply inferred from its name that a high damping ratio rubber is used in the vulcanization process, thus the bearing is featured with high damping ratio while the functions of conventional elastomeric bearings are also kept. The damping is generated by hysteretic loop area dissipating energy. Hysteretic behavior of HDRB is related with shearing strain and resultantly shear stiffness.

In addition to the common elastomeric bearings’ function, HDRB provides isolation and re-centering capabilities after the seismic events. The damping can be as high as to 20% while the common ones have only about 5%. By such large damping effect, the energy dissipation overwhelms other types of isolators.

The linear model is used to represent the stiffness and damping of the HDRB during design analysis stage. A changeable shear modulus G variable from 0.4 MPa to 1.3 MPa and an equivalent damping ratio (at shear strain, y=1) varying from 10% to 25% can help us design the desirable HDRB to meet structural seismic analysis. The non-linear behavior of the rubber compounds results in the fact that the shear modulus is higher while shear strain is low, allowing only minor movement due to forces such as wind.

Three different rubber compound:

Øsoft rubber compound (S),G= 0.4~0.6 MPa;

Ønormal rubber compound (N),G=1.0 MPa;

Øhard compound (H),G=1.2 MPa.

A schematic illustration of a round type HDRB (rectangular HDRB can also be designed)

hysteretic curve of HDRB

Materials

Refer to LRB

Dimensions

Consult IEC for details.

HDRB in production at IEC workshop and had supplied numerous projects in China and abroad