We use cookies to enhance your experience. Read our policy so you can understand the types of cookies we use, the information we collect using cookies and how that information is used.Privacy Policy

Close

Confirm choices

According to ETAG 032 code, The definition for Flexible Plug Expansion Joint (FPEJ) refers to an in-situ poured joint comprising a band of specially formulated flexible material (binder and aggregates), which also forms the surfacing, supported over the deck joint gap by thin metal plates or other suitable components.

Details

IEC Flexible Plug Expansion Joint (FPEJ)

IEC has supplied polyurethane(PUF) FPEJ in a number of projects in China, mainly for footpaths, ramifying highway intersections, etc. Image reveals an PUF FPEJ installed by IEC and serviced at ramifying highway roads in Yuguang expressway, Chongqing, China

According to ETAG 032 code, The definition for Flexible Plug Expansion Joint (FPEJ) refers to an in-situ poured joint comprising a band of specially formulated flexible material (binder and aggregates), which also forms the surfacing, supported over the deck joint gap by thin metal plates or other suitable components.

The conventional binder materials, which is largely used, is commonly based on bituminous mixture, or named as modified bitumen. After working with experts in material engineering at Southwest Jiaotong University, IEC develops polyurethane (PUF) as the paving material due to its longevity performance and perfect choice for low-noise during traffic impact, for movement less than 100mm.

PUF PFEJ installed by IEC at Yuguang expressway, 2020

Merits:

üDriving comfort

Due to being seamless of PUF joint, the beam deck has no visible gaps, which can effectively reduce vehicle impact. The polyurethane material has excellent elasticity and vibration damping performance, which can absorb the impact and vibration generated when vehicles pass through the expansion joint.

üLongevity

Polyurethane is a polymer synthetic material with stable performance and simple processing. It has the advantages of wear resistance, oil resistance, water resistance, temperature resistance, fatigue resistance, corrosion resistance, and easy repair.

üImpermeability

Polyurethane material has good adhesion properties with concrete and steel plates, and can form a continuous waterproof layer with the roadbed waterproof layer, effectively preventing water leakage on the bridge deck.

üShallow block-out

The installation block-out is very shallow, which has minimum damage to the beam structure or affecting the beam design. It is especially suitable for thin-walled beam structures.

üEast&fast installation/repair

The overall structure of PUF joint is simple. Polyurethane can be cast in one go, and there are not many requirements for installation equipment and labor. Traffic can be opened 48 hours after casting.

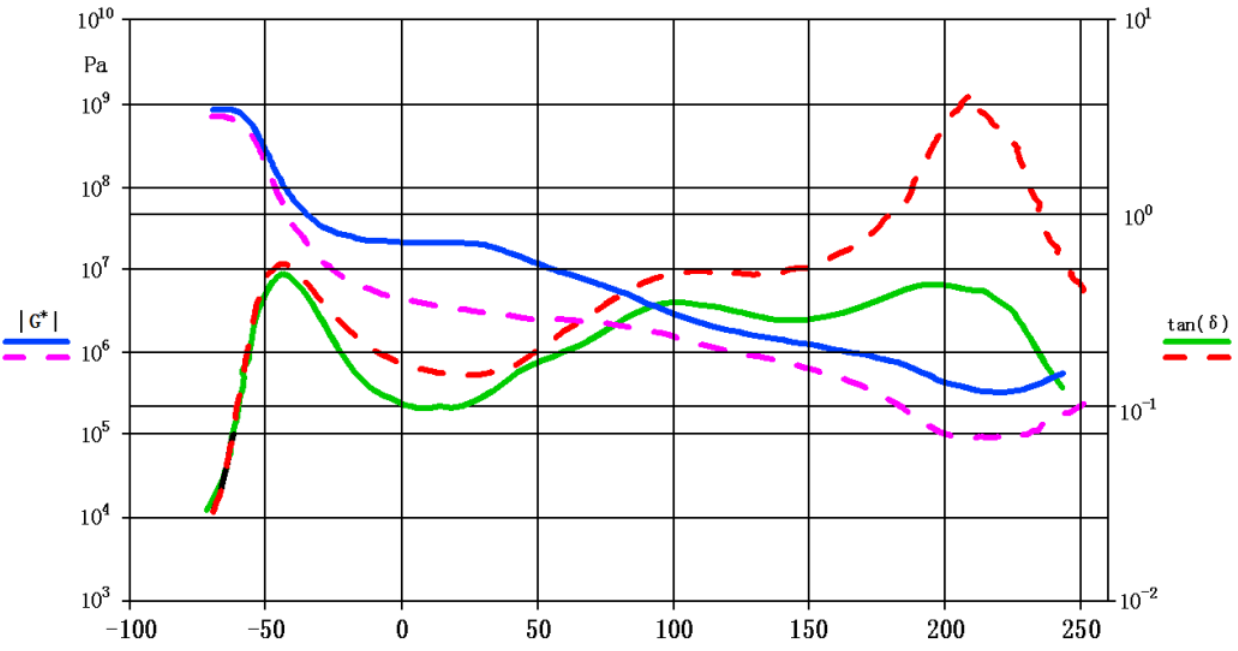

IEC carried out full-scale testing of PUF in-house simulating the actual wheel traffic. Testing lasted 3030h (126 days) with temperature range from -60℃ to 250℃. Testing results show the shear modulus G and the loss factor tanδ behaved to ideal levels, as following image showing.

Relationship between shear modulus G and loss factor tanδ concluded from testing

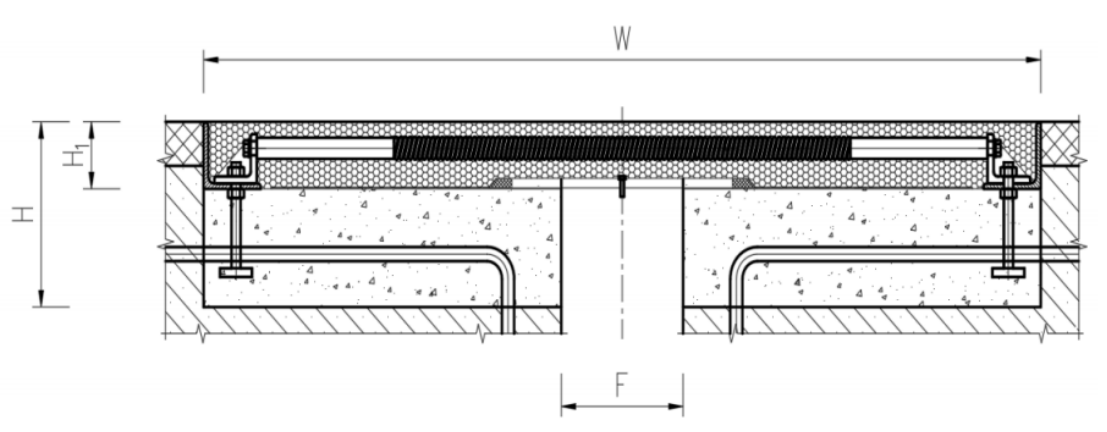

Section view of PUF joint

code | movement(mm) | beam gap | PUF joint size | block-out depth | |

F(MM) | W(MM) | H1(MM) | H*(MM) | ||

PUF40 | 40 | 30-40 | 450 | 60 | 160 |

PUF60 | 60 | 30-60 | 550 | 60 | 180 |

PUF80 | 80 | 52-80 | 700 | 60 | 200 |

PUF100 | 100 | 60-100 | 850 | 60 | 220 |

items | unit | requirement | |

solid content | % | ≥99.5 | |

hardness | IRHD | 65±5 | |

elasticity modulus | MPa | ≤2.5 | |

tensile strength | MPa | ≥10 | |

elongation at break | % | ≥650 | |

tear strength | N/mm | ≥15 | |

brittleness temprature | ℃ | ≤-50 | |

peel strength (with steel plate),-40±2℃,23±2℃,+60±2℃ | N/MM | ≥8 | |

tensile strength after bonding with concrete,-40±2℃,23±2℃,+60±2℃ | MPa | ≥1.5 | |

Leveling | h | ≥0.5 | |

surface drying time | h | ≤2 | |

body drying time | h | ≤12 | |

aging | appearance | - | no crack |

hardness | IRHD | ±5 | |

tensile strength | % | ±20% | |

elongation at break | % | ±20% | |

Consult IEC engineers for details.